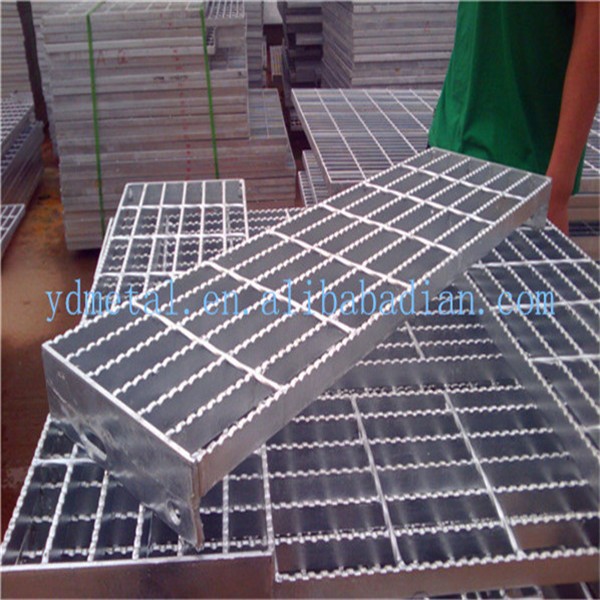

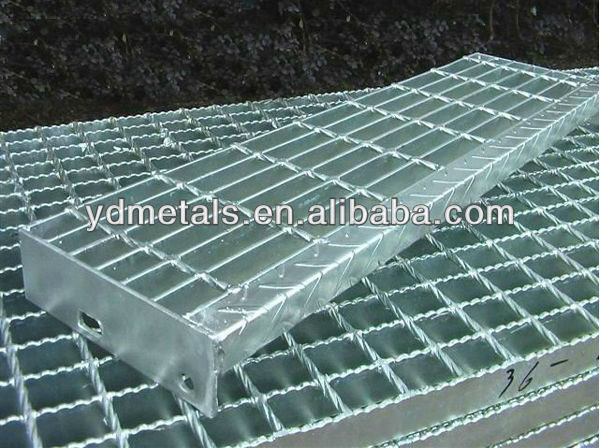

Stair Treads

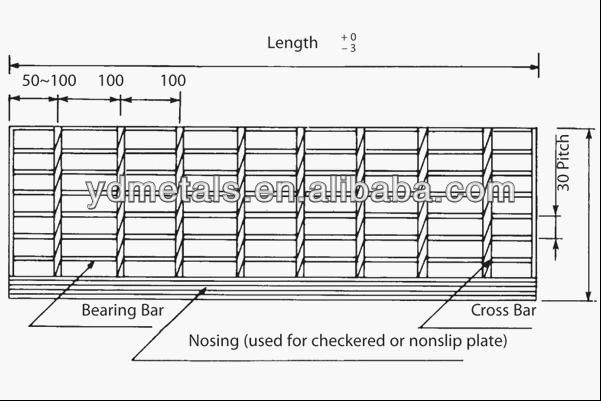

Stair tread creates a permanently slip resistant surface that is resistant to elements such as grease, dust and oil. When retrofitting over concrete steps, non-slip stair treads is routinely mounted into masonry anchors. Stair treads have become an integral safety component for extreme wear longevity and continual safety.They are available in thicknesses of 1/8″ up to 1/2″ and standard depths of 8″ – 12″. It’s important that the correct grating load bar size and grating type is used based on the required stair tread span and loading. The table below is a basic guide used to establish the correct grating type required.

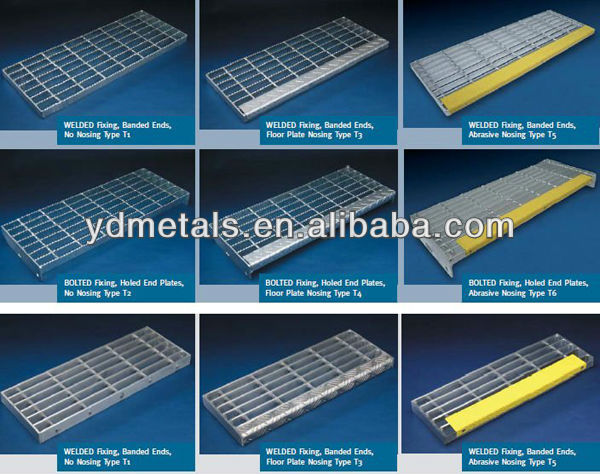

Stair Tread Types:

1>.Expanded metal stair tread

2>.Grating stair tread

3>.Perforated stair tread

4>Welded steel stair tread

Finished:

Self colour

Painted

Hot dipped galvanized

Advantages:

* Stair treads provide a durable walking surface but features benefits like grating which allow for drainage and air flow. It ensure slip resistance for many years to come.

* Stair treads have a protective finish such as paint or galvanizing. Without this surface treatment, stair treads can rust easily if exposed to moisture. Therefore it should be primed, painted or hot dipped galvanized to prevent corrosion. Hot dipped galvanizing is the preferred method for corrosion resistance.

* Non-slip galvanized stair treads are formed to job specifications. Treads can be formed into a channel to completely cover an existing slippery stair.

* Stair treads are easily retrofitted over existing concrete, grating or unsafe diamond checker plate assemblies. It can be welded directly onto current treads or can be bolted in place.

Applications:

Stair tread bar grating is a great choice for many industrial flooring applications. Smooth or serrated surfaces are available depending on your project needs for stair tread bar grating. Some common applications include:

Flooring

Walkway

Catwalk

Drain

Deck

Architectural

Package: